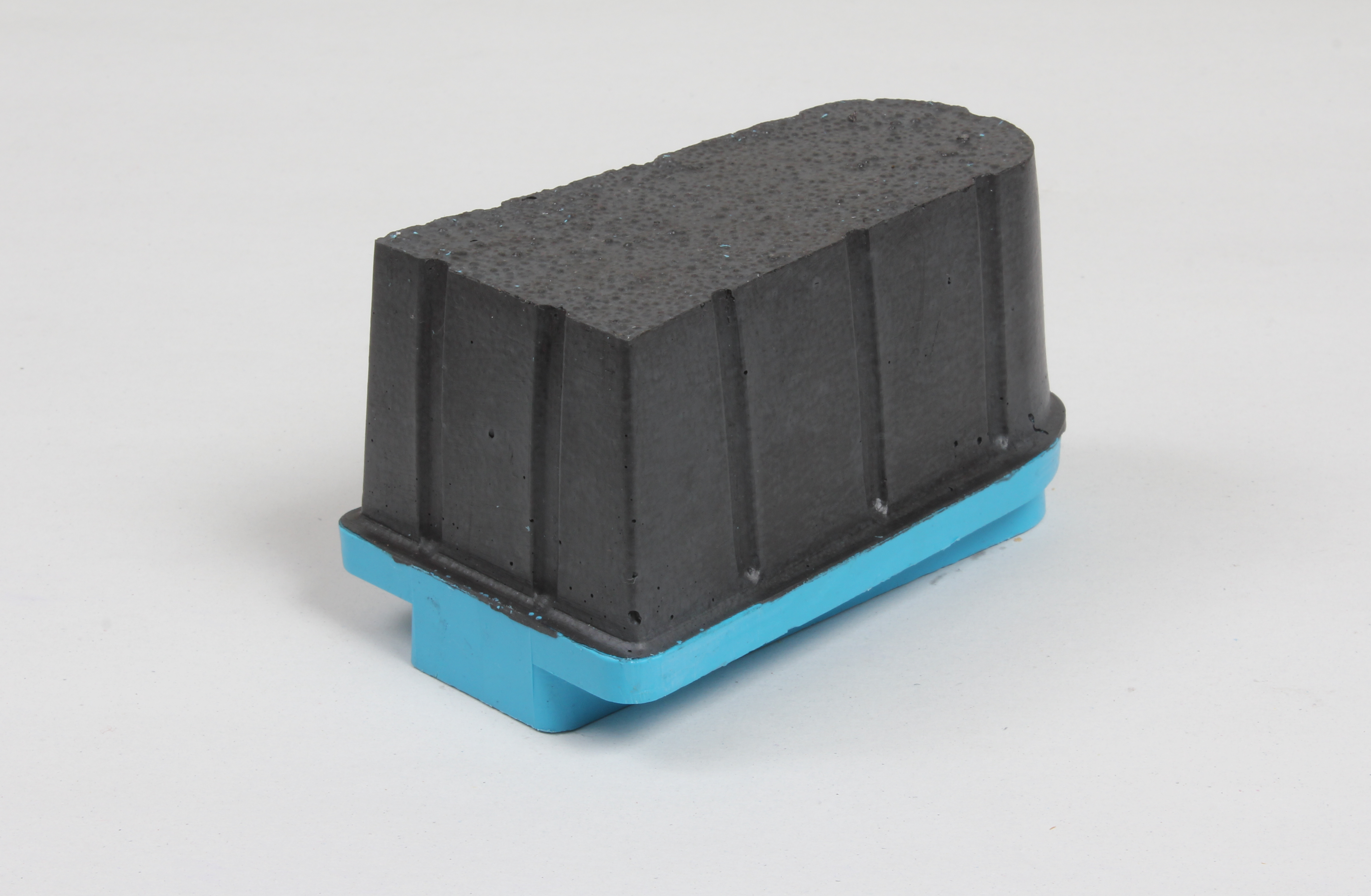

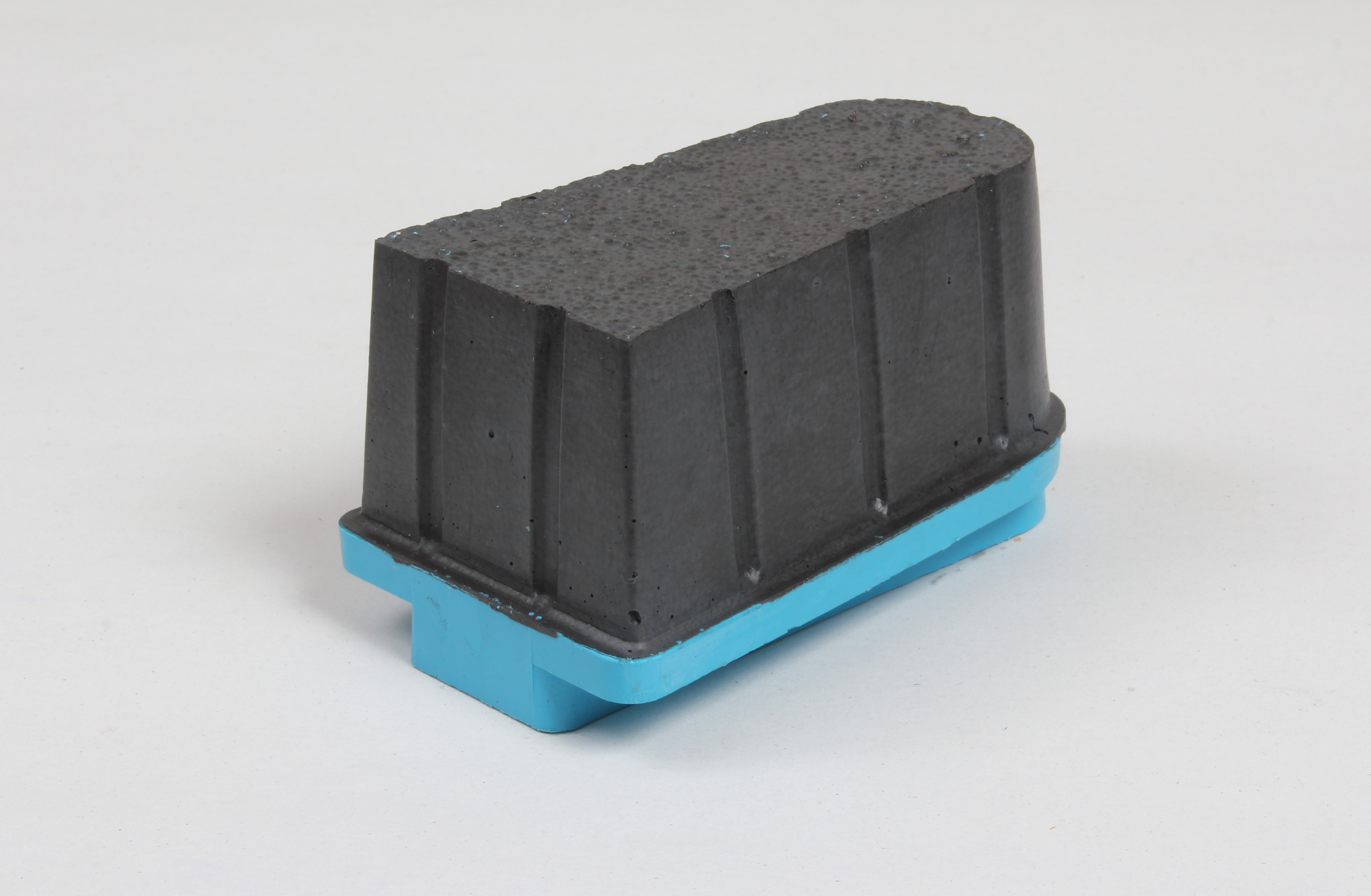

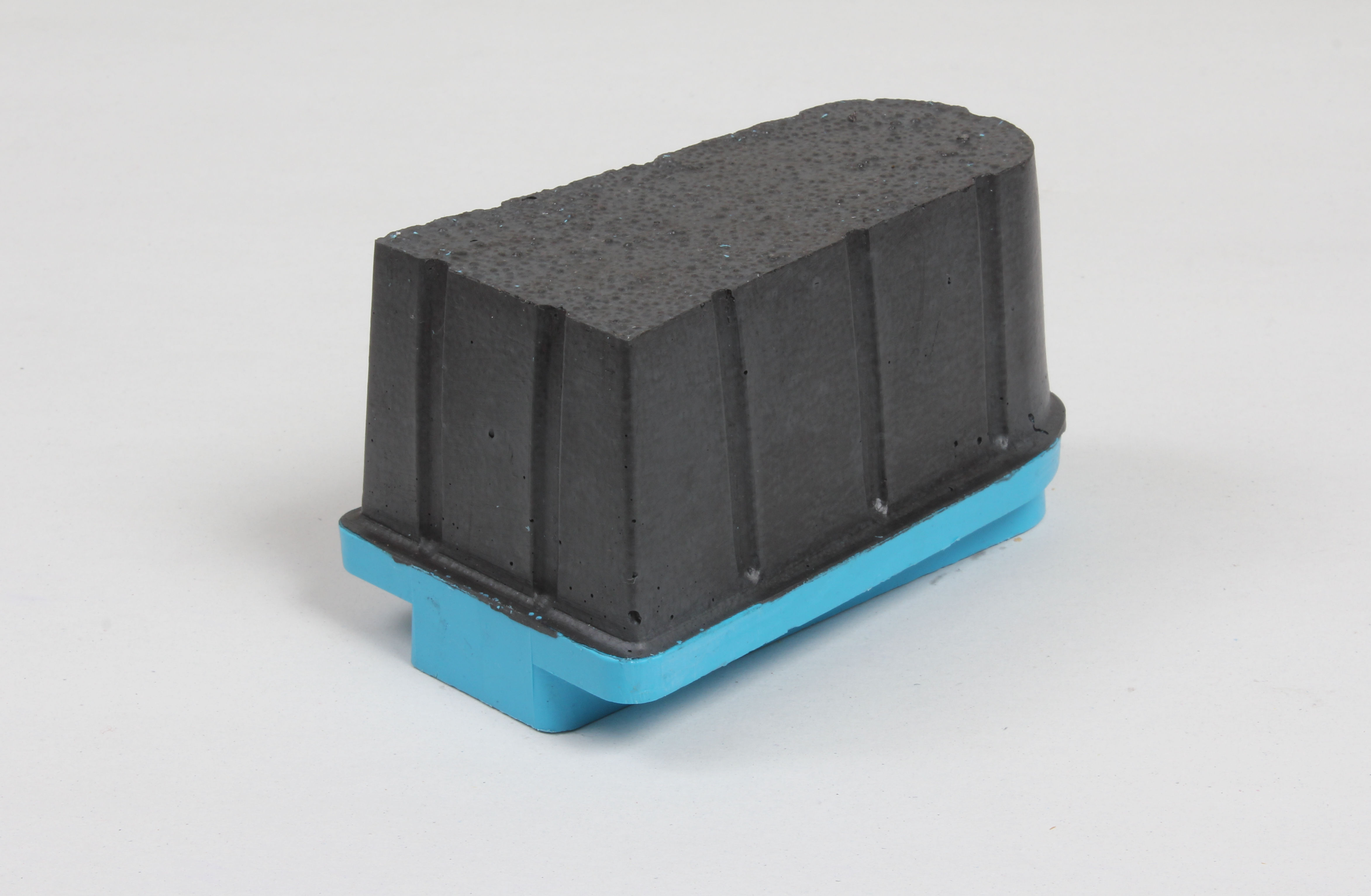

FICKERT FINAL 140

Price 300 INR/ Piece

MOQ : 2 Pieces

FICKERT FINAL 140 Specification

- Bonding

- Resin bond, Magnesite bond (varies by type)

- Shape

- Rectangular

- Grain Type

- Silicon Carbide, Aluminum Oxide

- Chemical Composition

- SiC or Al2O3 base, with bonding matrix

- Backing

- Plastic or Bakelite

- Toughness

- High structural toughness for heavy-duty grinding

- Hardness

- Medium to Hard (customizable)

- Material

- Abrasive-bonded composite

- Type

- Abrasive Fickert

- Grain Sizes

- 36, 46, 60, 80, 120, 180, 220, 320, 400, 600, 800, 1200, 1500, 1800, 2200, 3500

- Rolls Size

- 140 mm length (Fickert size)

- Strips Size

- 140 x 40 x 21 mm (typical, custom available)

- Suitable Machines

- Automatic line polishing machines, manual polishers

- Finishing Quality

- Enables high-gloss, smooth surface finish

- Odor

- Odorless during use

- Water Resistance

- Yes, suitable for wet applications

- Lifespan

- Long life, highly wear-resistant

- Application

- Final stage polishing and grinding for granite and engineered stone surfaces

- Color

- Gray, Green, White, Red (depends on grit and type)

- Recommended Use

- Marble, granite, artificial stone, quartz slabbing

- Edge Retention

- Excellent edge precision and retention during polishing

FICKERT FINAL 140 Trade Information

- Minimum Order Quantity

- 2 Pieces

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 5 Days

About FICKERT FINAL 140

Experience elite performance with the FICKERT FINAL 140, your crowning solution for final stage polishing and grinding on granite and engineered stone surfaces. Now available at a Special Rate with a notable Price Cut, reserve yours for superior finishing quality. This praiseworthy abrasive fickert boasts long life, outstanding edge retention, and odorless operation during wet usage. It comes in Gray, Green, White, and Red shades based on grit, with a highly wear-resistant build and elite grain choices from 36 to 3500. Suitable for marble, granite, artificial stone, and quartz slabbing, its the preferred choice for automatic line machines and manual polishers. Distributed by Indias trusted manufacturers, suppliers, and traders, FICKERT FINAL 140 sets the standard for high-gloss, smooth surface excellence.

Elite Application Performance

FICKERT FINAL 140 is used for final stage polishing and grinding, delivering praiseworthy results on granite, engineered stone, marble, and quartz surfaces. Applied as an abrasive-bonded composite, it serves both automatic line polishing machines and manual polishers. Its usage type is ideal for heavy-duty, wet processing, enabling the crowning touch to surfaces with high-gloss, smooth finishes and exceptional edge retention. Choose FICKERT FINAL 140 for elite surface perfection across your stone workshop.

Global Transportation & Export Policy

FICKERT FINAL 140 is supplied via FOB major Indian ports, ensuring seamless international transportation and timely delivery after purchase order approval. Sample policies are designed to accommodate express shipping requests, allowing you to evaluate quality before bulk procurement. The main export markets include Asia, Europe, Africa, and the Middle East, positioning the FICKERT FINAL 140 as an elite choice for worldwide traders, distributors, manufacturers, and suppliers.

Elite Application Performance

FICKERT FINAL 140 is used for final stage polishing and grinding, delivering praiseworthy results on granite, engineered stone, marble, and quartz surfaces. Applied as an abrasive-bonded composite, it serves both automatic line polishing machines and manual polishers. Its usage type is ideal for heavy-duty, wet processing, enabling the crowning touch to surfaces with high-gloss, smooth finishes and exceptional edge retention. Choose FICKERT FINAL 140 for elite surface perfection across your stone workshop.

Global Transportation & Export Policy

FICKERT FINAL 140 is supplied via FOB major Indian ports, ensuring seamless international transportation and timely delivery after purchase order approval. Sample policies are designed to accommodate express shipping requests, allowing you to evaluate quality before bulk procurement. The main export markets include Asia, Europe, Africa, and the Middle East, positioning the FICKERT FINAL 140 as an elite choice for worldwide traders, distributors, manufacturers, and suppliers.

FAQs of FICKERT FINAL 140:

Q: How does FICKERT FINAL 140 benefit the final polishing process for granite surfaces?

A: FICKERT FINAL 140 delivers a high-gloss, smooth finish with excellent edge retention, ensuring the end product looks elite and professional while maximizing durability on granite surfaces.Q: What machines are compatible with FICKERT FINAL 140?

A: This product is suitable for automatic line polishing machines and manual polishers, offering versatile usage across various stone processing facilities.Q: When should FICKERT FINAL 140 be used during the stone finishing process?

A: It is recommended for the final stage polishing and grinding, after rough shaping and preliminary sanding, to achieve crowning perfection on granite, marble, or quartz slabbing.Q: Where can FICKERT FINAL 140 be purchased and shipped to globally?

A: FICKERT FINAL 140 is available from authorized Indian distributors, manufacturers, suppliers, and traders, and it can be shipped worldwide through major export markets via FOB ports.Q: How is the products resilience during heavy-duty wet applications?

A: The FICKERT FINAL 140 boasts high structural toughness and is highly wear-resistant, performing reliably under continuous wet usage without compromising lifespan or finishing quality.Q: What are the advantages of its material and bonding types?

A: Made from abrasive-bonded composites, with customizable resin or magnesite bonding, the product offers medium to hard hardness options, ensuring precise results and extended durability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Yash Abrasive

GST : 08AAGPJ4317H1ZU

GST : 08AAGPJ4317H1ZU

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS